Solutions

01

From a single-load transport to total freight management, we partner with trusted third-party carriers or asset-backed affiliates to manage your supply chain and logistics challenges smoothly, safely, and efficiently.

Learn more02

The GTI Group’s transportation management solutions combine our highly trained logistics professionals with full-service, cutting-edge technology to serve as your supply chain and logistics team.

Learn more03

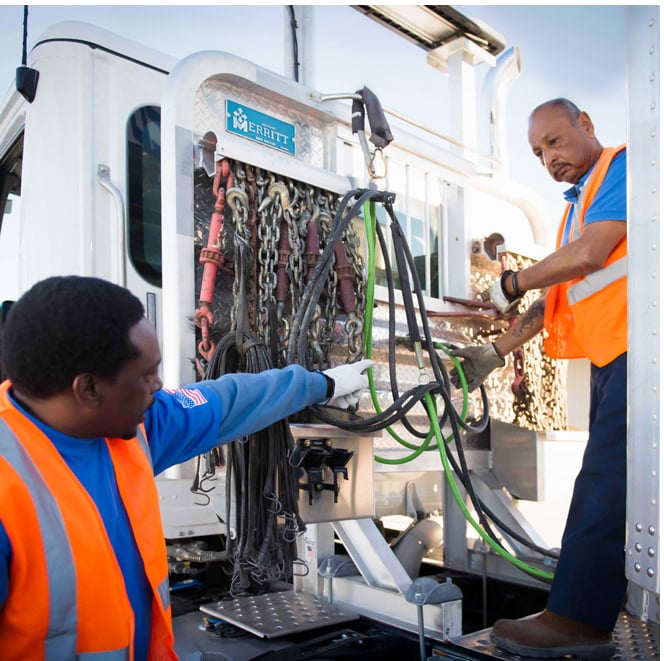

By leveraging our deep understanding of market conditions—hard-won knowledge we’ve developed over decades of business— we offer thoughtful and thorough asset-based trucking services across North America.

Learn moreMore than thirty years of strategic mergers have resulted in one carefully constructed company that’s been shaped by practical experience in virtually every segment of freight transportation.

Learn About The GTI Group

We don’t just drive. We drive change—across the entire trucking industry. Apply as a GTI driver and enjoy competitive pay, well-maintained trucks, and the most important benefit of all—more time at home.

Drive with The GTI GroupGTI Group

Canada Cartage and The GTI Group’s combined size, revenue and volume enabled it to make four Transport Topics’ 2024 Top 100 lists, announced on Friday, April 12, 2024. The lists recognize the largest companies in North America based on gross revenue for the most recent 12-month period.

Read NowGTI Group

Long-time client Siegwerk awarded GTI USA with an extraordinary effort medal in recognition of our outstanding service over the last four years. GTI USA Senior Vice President of Operations Ben Sun also received a warehouse regiment medal for his efforts to improve efficiencies within Siegwerk’s warehouse and shipping departments during their SAP transition.

Read NowGTI Group

First superload collaboration completed between GTI USA and Precision

When one of our operating unit GTI USA’s longtime clients approached us with a unique challenge, GTI USA and Precision Specialized worked together to make it happen.

GTI Group

Last month, Precision and Jetco met with Kiewit in Houston and presented Precision's recently completed project. What was the scope of the project? Transporting 10 massive modules from Edmonton, AB, to multiple sites in Ottawa, ON.

The modules, ranging from 87,000 to 113,000 lbs., posed significant logistical challenges with dimensions of 60’ x 16’3” x 14’ and 50’ x 16’3” x 14”. Loaded dimensions reached an impressive 165’ x 20’ x 15’5”.

Precision's choice of a 13-axle rear steer perimeter trailer proved effective for the extensive 2,392 permitted miles journey. The modules traveled from Edmonton to a stage yard near Ottawa, then an additional 40-70 miles to their final delivery sites.

The move spanned 10 transit days, transitioning from daytime travel to a 4-6 hour night move. Despite the challenges, Precision's meticulous planning ensured a smooth journey.

An essential aspect of this success was Precision's transparent presentation of lessons learned to Kiewit. This collaborative approach reinforces the industry's commitment to continuous improvement and adaptability in the face of complex logistical challenges.

Customer service representatives, dispatchers, administrators, logistic specialists, warehouse personnel—come join us and be a catalyst for change in the transportation industry.